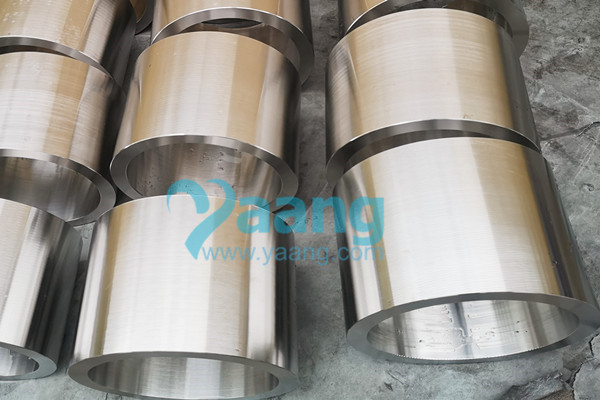

Type: 2.4819 Yopanga mphete

Zida: Nickel Alloy C276 (Hastelloy C276/UNS N10276/W.Nr. 2.4819)

Kukula: OD: 506.8 mm

kukula: 404.8 mm

Kutalika: 51 mm

Standard: Forgings Forgings / Non-standard Forgings

Hastelloy C-276 ndi chiyani

Hastelloy C-276 ndi Ni Mo CR superalloy yowonjezeredwa ndi tungsten, yomwe ili ndi kukana kwa dzimbiri kwabwino kwambiri m'malo ovuta osiyanasiyana. Kuchuluka kwa Ni ndi Mo kumapangitsa kuti aloyi yachitsulo ya Ni ikhale yolimba kwambiri ku maenje ndi kuwonongeka kwa ming'alu pochepetsa chilengedwe, pomwe CR imasamutsa magwiridwe antchito a anti-oxidation medium. Kutsika kwa carbon kumatha kuchepetsa mpweya wa carbides powotcherera, kuti asunge kukana kwa dzimbiri kwa mawonekedwe awotcherera. Izi aloyi faifi tambala ndi kugonjetsedwa ndi mapangidwe mbewu malire mpweya mpweya mu HAZ, kotero ndi oyenera ntchito mankhwala ambiri ndondomeko pansi kuwotcherera zinthu.

Kupanga kwa Hastelloy C-276

Aloyiyo imapangidwa pakati pa 2250/1750ºF (1230/955ºC) kutsatira kunyowa pa kutentha kwa mphindi 30 pa inchi ya billet kapena makulidwe a gawo la ingot. Kupanga kuyenera kuyambika nthawi yomweyo katunduyo amachotsedwa mu ng'anjo yotenthetseranso ndipo kuchepetsa 25/40% kumathandizira kusunga kutentha kwamkati momwe kungathekere. Kuti zisawonongeke ndi dzimbiri, zigawo zopangira zimayenera kutsekedwa. Onani Chithandizo cha Kutentha.

Chithandizo cha Kutentha Hastelloy C-276

Aloyi nthawi zambiri imaperekedwa ngati njira yothetsera vutoli. Kuchiza kumeneku kumachitika pa 2050ºF (1120ºC) ndikutsatiridwa ndi kuzimitsa madzi kapena mpweya wozizira kwambiri. The mankhwala ikuchitika pambuyo yotentha ntchito kuonetsetsa momwe akadakwanitsira dzimbiri kukana ndi pakati ozizira-ntchito ntchito.

Kuthekera kwa Hastelloy C-276

Aloyiyo amaonedwa kuti ndi yapakati mpaka yovuta kupanga makina, koma imatha kupangidwa pogwiritsa ntchito njira wamba. Aloyiyo imakhala ndi chiwopsezo chachikulu choumitsa ntchito, ndipo kukonza bwino kumafuna makina olimba komanso opitilira mphamvu, zida zakuthwa, makamaka zokhala ndi carbide, komanso zolemetsa, zopatsa mphamvu nthawi zonse.

Weldability wa Hastelloy C-276

Aloyi amawotchera mofanana ndi C-22 alloy. Gasi-tungsten-arc kuwotcherera (GTAW) ndi kuwotcherera-chitsulo-arc (SMAW) amagwiritsidwa ntchito powotcherera aloyi ya C-276.

Ndibwino kuti alloy ikhale mu njira yothetsera kuwotcherera, komanso kuti C-276 filler zitsulo zigwiritsidwe ntchito.

Kuwotcherera kwa submerged-arc sikuvomerezeka pazitsulo izi chifukwa pali kutentha kwakukulu ndi njira iyi komanso kuzizira pang'onopang'ono kwa weld. Komanso kuwotcherera kwa Oxyacetylene sikuvomerezedwa, chifukwa cha kuopsa kwa kaboni mu weld.

Hastelloy C-276 Forgings Equivalent Standard

| Standard | UNS | WNR. | AFNOR | EN | JIS | OR | GOSI |

| Chithunzi cha C276 | N10276 | 2.4819 | - | Chithunzi cha NiMo16Cr15W | NW 0276 pa | ЭП760 | ХН65МВУ |

Chemical Composition - Aloyi C276 (Hastelloy C276/UNS N10276)

|

aloyi

|

%

|

Ni

|

Cr

|

Mo

|

Fe

|

W

|

Co

|

C

|

Mn

|

Si

|

V

|

P

|

S

|

|

N10276

|

Mphindi.

|

Chotsalira

|

14.5

|

15.0

|

4.0

|

3.0

|

|||||||

|

Max.

|

16.5

|

17.0

|

7.0

|

4.5

|

2.5

|

0.010

|

1.0

|

0.08

|

0.35

|

0.04

|

0.03

|

Chemical Composition - DIN 17744 2.4819 XNUMX

|

aloyi

|

%

|

Ni

|

Cr

|

Mo

|

Fe

|

W

|

Co

|

C

|

Cu

|

Mn

|

Si

|

V

|

P

|

S

|

|

2.4819

|

Mphindi.

|

Kupumula

|

14.5

|

15.0

|

4.0

|

3.0

|

||||||||

|

Max.

|

16.5

|

17.0

|

7.0

|

4.5

|

2.5

|

0.010

|

0.050

|

1.0

|

0.08

|

0.35

|

0.020

|

0.015

|

Makina & Katundu Wakuthupi - Aloyi C276 (Hastelloy C276/UNS N10276)

| kachulukidwe | 8.89 g / cm3 |

| Melting Point | 1370 ° C (2500 ° F) |

| Kulimba kwamakokedwe | Psi - 1,15,000, MPa - 790 |

| Mphamvu Zokolola (0.2% Offset) | Psi - 52000, MPa - 355 |

| Kuphatikiza | 40% |

Zofotokozera - Aloyi C276 (Hastelloy C276/UNS N10276) |

|||

| ndodo | ASTM B574 | ||

| Mapepala & Plate | ASTM B575 | ||

| Chubu & Chitoliro | ASTM B622, ASTM B626, ASTM B619 | ||

| Kupanga | ASTM B564 | ||

Chifukwa Forged mphete?

Mavuto omwe amapezeka ndi mphete zachitsulo amatha kutsatiridwa ndi kupanga zitsulo. Mphete zoponya nthawi zambiri zimakhala ndi mphamvu zopanda malire komanso kukhulupirika. Mphete zokulungidwa ndi zomangika kapena zodulidwa kuchokera m'mbale zimatha kutopa komanso kunyamula zinthu zambiri komanso ndalama zolipirira.

Njira yopangirayi imapanga mphete zoyendetsedwa bwino ndi tirigu, zomwe zimapereka mphamvu ndi kukana kukhudzidwa ndi kutopa komwe sikumapezeka mumphete zodulidwa kuchokera ku mbale kapena zokulungidwa ndi kutenthedwa.

Ubwino Wopangira mphete

- Kupeza umphumphu wapangidwe

- Kukulitsa kulimba

- Kuthandizira kusinthasintha kwa kukula

Kulemera mpaka 60,000 lbs. muzinthu zonse zachitsulo komanso zopanda chitsulo. Njira yopangirayi imapanga mphete zoyendetsedwa bwino ndi tirigu, zomwe zimapereka mphamvu ndi kukana kukhudzidwa ndi kutopa komwe sikumapezeka mumphete zodulidwa kuchokera ku mbale, kapena zopindidwa ndi kutenthedwa.

Tekinoloje yopanga mphete yabodza

Liti mphete zopangira amapangidwa, njira zotseguka zakufa zimatsatiridwa kuti ogwira ntchito athe kupanga mphete zopanda msoko. Njira yapadera yogudubuza imapangitsa mphete iliyonse kukhala yokhazikika komanso yosalala bwino. mphete zonse zopukutira zimatha kupirira kulolerana kokhazikika ndikukwaniritsa zofunikira zamakampani. Mphete za Mandrel zimapangidwira makasitomala omwe amafunikira mphete zolemera kapena mphete zocheperako.

Mgayo umagwiritsidwa ntchito ngati mphete zopangira zopanda msoko zimapangidwa m'mafakitale opanga. Chifukwa cha kukula kosiyanasiyana kwa mphero yogubuduza, kukula kwakunja kwa mphete iliyonse kumakhala kosiyana. mphete yaing'ono kwambiri nthawi zambiri imalemera pafupifupi mapaundi 300, ndipo mphete yayikulu kwambiri nthawi zambiri imalemera mapaundi opitilira 300000.

Njira yopanga mphete zopukutira

Pa gawo loyamba, chitsulo chozungulira chimasandulika kukhala donati wopanda kanthu. Ogwira ntchitowo adatenthetsa donatiyo mpaka pamwamba pawoneka bwino. Chitsulocho chimayikidwa pa mandrel kapena idler. Kenako, pansi pa kupanikizika kwamphamvu, wodzigudubuza amapita ku galimoto yoyendetsa galimoto. Amachepetsa makulidwe a khoma pozungulira mosalekeza.

Opanga ambiri amatha kupanga mphete zopanda msoko muzosintha zosiyanasiyana. Mabizinesi ambiri amafuna mphete zathyathyathya, mphete za cylindrical ndi mphete zomwe zimawoneka ngati zochapira. Kutalika kwa mphete iliyonse kumasiyananso; Chogulitsacho chikhoza kupangidwa kukhala inchi imodzi kapena kupitirira mamita asanu ndi anayi. Komabe, kutalika kwa chiŵerengero cha makulidwe nthawi zambiri kumakhala pakati pa 1:16 ndi 16:1. Ngati kasitomala akusowa mphete zingapo zokhala ndi gawo lalikulu, chithandizo chapadera chimafunika. Kawirikawiri, mphete zamakona ndizofala kwambiri, chifukwa mapangidwe awo ndi osavuta.

- Khwerero 1: Sungunulani ndi Thirani zitsulo zamadzimadzi kuti mupange ingot yachitsulo;

- Khwerero 2: Ingot yachitsulo yotentha ndi yopanda kanthu kuti mupange zitsulo;

- Khwerero 3: Dulani zitsulo kuti mupeze billet mwa kudula makina;

- Khwerero 4: Kukhumudwa ndi makina osindikizira / nyundo kuti mutenge keke yozungulira;

- Khwerero 5: Menyani ndi kuboola kuti musasowe kanthu polemba zida;

- Gawo 6; Kugudubuza mphete ndi makina opangira mphete;

- Khwerero 7: Pangani kutentha kutentha ndi Machining.

Yaang Tailored Solutions

- Zing'onozing'ono kapena zazikulu zotseguka zimafa kapena mphete zopindika

- Mpaka 252 ″ pazipita OD

- Kufikira 49 ″ kutalika kwa nkhope

- Zolemera mphete zozungulira mpaka 60,000 lbs., Zolemera zotsegula mpaka 300,000 lbs.

Kukonzekera kwapansi monga kutentha, kuyesa, kukonza, kugawa magawo, kugawanitsa kapena kupatukana zonse zitha kuchitika mnyumba.

Yaang Forge Kusiyana

Ku Yaang, tikudziwa kufunikira kopeza magawo anu munthawi yake, monga momwe timayembekezera. Komabe, kwa makasitomala atsopano pakupeza ma forgings, kuyitanitsa zopangira zomwe zingakwaniritse zofunikira zonse zogwiritsira ntchito kumapeto kungakhale kovuta, ndichifukwa chake kupeza wothandizira wodalirika ndi mnzake ndikofunikira. Ogwira ntchito athu ali pano kuti awonetsetse kuti polojekiti yanu imayenda bwino ndi zomwe tapanga popereka:

- Forge Design & Engineering Guidance

- Anamaliza Machining Zosankha

- Ndemanga ya Metallurgical, NDE & Kuyesa Kowononga

- Zopangidwa Zabodza

Timapereka ma forgings ambiri mumitundu yonse komanso yapadera kuti tikwaniritse zosowa zanu.

Mawonekedwe Ovuta

- Mabotolo

- Step Shafts, Eccentric Shafts & Rotor Shafts

- Mabowo

- Ma Hubs & Zida Zopangira

- Zopangira Zopangira & Zokulungidwa

- Semi-Closed Die

- Ma discs & Blanks